|

|

|

FLOWROX FLOWROX

Flowrox is the benchmark in heavy duty valves, pumps and

systems with over 30 years of experience in elastomer

technology and more than 100,000 global deliveries. Flowrox

slurry equipment is an environmentally friendly and cost

effective solution for demanding industrial flow control

applications.

|

|

|

|

FLOWROX VALVES

| |

Flowrox

Pinch Valves Flowrox

Pinch Valves |

|

| |

|

|

|

| |

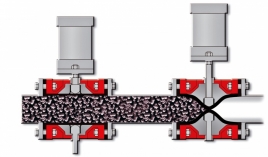

Pinch valves are ideal solutions where shut-off and

control applications involve abrasive or corrosive

slurries, powders or coarse substances. Flowrox

provides pinch valves with enclosed, open, sealed and

general line valve bodies. We provide tailor-made flow

control solutions precisely in accordance with the

customer specification.

Pinch Valve Benefits:

- Full bore structure with 100 % tight shut-off

- Only the inside sleeve is in contact with the

process medium

- Self-cleaning Flowrox valves provide seal tight

shut-off even if solids have built up on the sleeve

wall. When compressed, any crystallized particles

flake off the sleeve surface.

- Modular design with three main components

- Standard size range from 25 mm to 1.000 mm

- Temperatures: -50°C to +160°C

- Operating pressures: vacuum to 100 bar .

Available Models:

|

|

|

|

|

|

PVE Pinch

Valve

|

PV Pinch

Valve

|

PVG Pinch

Valve

|

PVEG Pinch

Valve

|

|

|

| |

|

|

|

| |

|

|

|

| |

Flowrox

Slurry Knife Gate Valves Flowrox

Slurry Knife Gate Valves

|

|

| |

|

|

|

| |

LKW LKW

Flowrox Heavy Duty Knife Gate Valves are built with a

cast body and they feature a heavy-duty stainless

steel blade. Removable seats on either side of the

gate provide a bi-directional bubble tight seal, with

no metal parts in contact with the slurry flow.

Flowrox slurry knife gate family includes Wafer

(LKW), Flanged (LKF) and High

Pressure (LKH) valves. Standard pressures are up

to 10 bar for LKW/LKF and 20 bar for LKH.

Feature & Benefits:

- Double seat design for heavy duty slurry service

- Easily replaceable ring sleeves

- Full bore

- No metal parts in contact with the flowing slurry

- Bubble tight shut-off

|

|

| |

|

|

|

| |

|

|

|

| |

Flowrox Rotary Disc Valves Flowrox Rotary Disc Valves |

|

| |

|

|

|

| |

LRD LRD

Flowrox Rotary Disc Valves (LRD) have a

unique rotating disc that rotates on every cycle.

Heavy duty LRD is able to handle the most demanding

slurries with standard pressured are up to 100 bar.

Rotary disc valves are suited for

several applications e.g. in Mining and Metal

Industries, Mineral Processing or Water and Waste

Water Treatment. Flowrox can also supply non-standard

diameters and special pressures on request.

Features & Benefits:

|

|

| |

|

|

|

FLOWROX PUMPS

| |

Flowrox

Peristalic Hose Pumps Flowrox

Peristalic Hose Pumps |

|

| |

|

|

|

| |

Flowrox peristaltic hose pump range includes three

series of pumps that are ideal for Transferring

(LPP-T), Dosing (LPP-D) and Metering

(LPP-M) duties. Flowrox hose pumps incorporate

an advanced design, which eliminates friction,

maximizes hose life time and lowers energy

consumption.

A peristaltic pump is a type of positive

displacement pump used for pumping a variety of

fluids. Flowrox Peristaltic Hose Pumps are designed

for the toughest industrial applications and are ideal

for abrasive, corrosive, viscous and crystallizing

media. Customer does not have to worry about

overheating even with high continuous flow rates and

the pump operation is trouble-free and consistent.

Energy efficiency, long hose life and low maintenance

need lead to substantial savings during the life cycle

of peristaltic pumps. In LPP-T and LPP-D

hose pumps these features are taken even further

thanks to their unique operating principle and rolling

design. Flowrox LPP-M metering pumps offer

superior accuracy for your processes. The non-enclosed

version of the pump is designed especially for OEM

processes.

Pinch Valve Benefits:

- Full bore structure with 100 % tight shut-off

- Only the inside sleeve is in contact with the

process medium

- Self-cleaning Flowrox valves provide seal tight

shut-off even if solids have built up on the sleeve

wall. When compressed, any crystallized particles

flake off the sleeve surface.

- Modular design with three main components

- Standard size range from 25 mm to 1.000 mm

- Temperatures: -50°C to +160°C

- Operating pressures: vacuum to 100 bar .

Available Models:

|

|

|

|

|

LPP-T for

Transfer

LPP-T transfer pumps

incorporate advanced rolling design which

eliminates friction and lowers energy

consumption. The roller is mounted on a

crankshaft creating eccentric rotation

during the 360 degree operating cycle.

Designed for heavy industrial duties with

the lowest life cycle costs, Flowrox hose

pumps are ideal for pumping various slurries

and dosing a wide range of abrasive,

corrosive, viscous or crystallizing media.

|

LPP-D for

Dosing

The Flowrox LPP-D dosing

pumps have a high turndown ratio making them

ideal for dosing and flow control. They

provide accurate dosing in all process

conditions as the pump discharge flow does

not depend on the pipeline pressure.

Operators do not have to worry about

overheating even with high continuous flow

rates. The pump operation is trouble-free

and consistent. 16 bar high pressure as well

as acid proof pump heads are also available.

|

LPP-M for

Metering

Accuracy of metering in any

application is the most vital property of a

metering pump. Flow rate of LPP-M metering

pump is not affected by variation of the

discharge pressure condition. Positive

displacement of the tube bore with zero slip

provides same output volume on every cycle.

The compression point of the tube acts as

self-cleaning check valve without clogging

risk providing clear flow path with no

possibility for vapour lock.

|

|

|

| |

|

|

|

| |

|

|

|

| |

Flowrox

Progressive Cavity Pumps Flowrox

Progressive Cavity Pumps

|

|

| |

|

|

|

| |

A progressive cavity pump is a type of positive

displacement pump and is also known as a progressing

cavity pump, eccentric screw pump or even just cavity

pump.

The Flowrox progressing cavity pump is designed for

the most demanding industrial slurry and paste pumping

applications, especially with high viscous or shear

sensitive liquids and sludges. Due to its unique

features and patented design, high efficiency and high

pressure are achieved with a shorter construction.

Flowrox utilizes a one of a kind, patented shaft and

seal allowing the mechanical shaft seal to be replaced

quickly and without dismantling or moving the entire

pump or its extended shaft and coupling. Combined with

a long service interval, this enables the highest

uptime possible.

Progressive Cavity Pump Selection:

- Series C pumps for demanding duties e.g.

in pulp & paper, mining & minerals and

chemical industries

- Series EL, a very compact solution for

environmental applications such as waste water

- Series E for various industrial

applications

- Series D pumps for dosing

|

|

| |

|

|

|

Visit Flowrox's Website

|